Facility

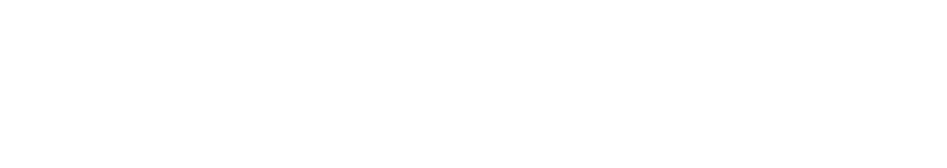

Ultra-high vacuum (UHV) STM

STM can image individual atoms/molecules on a solid surface. We measure size and shape of metal nanoparticles deposited on an oxide single-crystal surface and observe adsorption, diffusion, and reaction processes of reactant gases on the model catalyst surface.

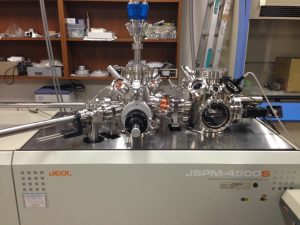

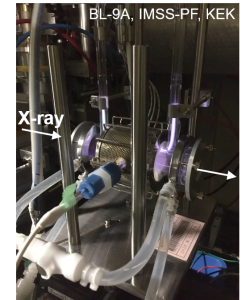

Operando PTRF-XAFS

Operando polarization-dependent total reflection fluorescence (PTRF)-XAFS technique is our original measurement method and can determine a three-dimensional structure of active metal sites on an oxide single-crystal surface while monitoring the progress of the catalytic reaction.

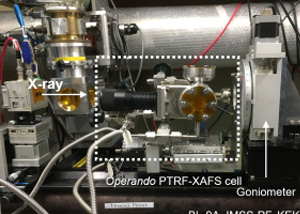

UHV multi-modal surface analysis chamber

X-ray photoelectron spectroscopy (XPS), temperature-programmed desorption (TPD), low energy electron diffraction (LEED), and high-pressure reactor are available in this UHV chamber. We can evaluate structure, electronic state, and catalytic reactivity of a model catalyst surface.

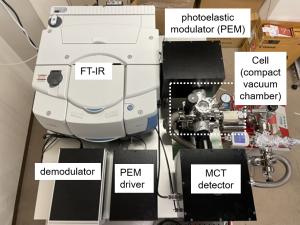

PM-IRRAS

By producing polarization-modulated infrared light at high speed through a photoelastic modulator and applying a reflection-mode measurement, IR spectrum only from surface adsorbed species on a model catalyst surface can be obtained in the presence of reactant gases.

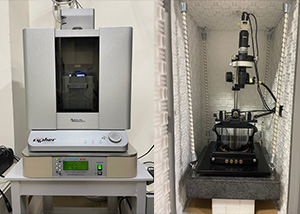

AFM/STM

AFM and STM measurements in air or under electrochemical conditions. They provide information on surface morphology at the nanoscale. We observe atomically flat oxide and metal single-crystal surfaces.

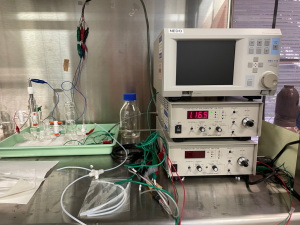

Potentiostat / Galvanostat

Electrochemical measurements such as cyclic voltammetry (CV). Used to confirm the flatness of single-crystal substrate surfaces and to evaluate electrocatalytic activity.

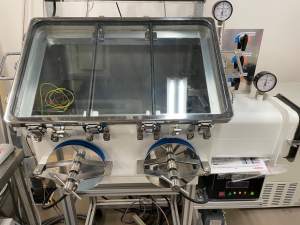

Glove box

Used for sample preparation and electrochemical measurements under inert atmosphere.

in situ XAFS cell for plasma catalysis

This quartz cell is designed for in situ XAFS measurements of powder catalysts during plasma-assisted catalytic reactions.